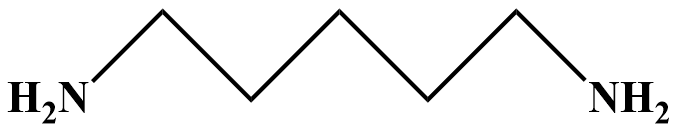

Pentamethylene diamine (PDA), also known as 1,5-diaminopentane, is an important five-carbon monomer. It is a colorless, smoky liquid with an ammonia-like odor, which is easily soluble in water and ethanol. Cathay uses renewable plant resources as the raw material to produce high purity bio-based PDA through a specific bioconversion process. Its carbon content from renewable resources is 100%.

PDA can be used in polyamides, pentamethylene diisocyanates (PDI), epoxy resin curing agents, organic synthesis intermediates, etc. Application fields include textiles, engineering materials, pharmaceuticalsns, pesticides, organic synthesis and other fields.

In 2014, Cathay realized a breakthrough in the PDA industrialization technology and completed the pilot plant test. After verification by international downstream customers, PDA was successfully applied to automobile surface paint, and this application has won the ECS Innovation Award.

The large-scale production of PDA is expected to solve the import dependence problem of adiponitrile, which is the core bottleneck of the development of the domestic double monomer polyamide industry. PDA provides our customers with new "biological manufacturing" materials made from renewable biomass raw materials.

Made from renewable plant-based raw

materials, Cathay's bio-based PDA has been analyzed and verified by a

third-party laboratory using the ASTM 6866 method to have a 100% renewable

carbon content. This effectively reduces the use of petrochemical-based

counterparts such as petroleum, thereby reducing carbon emissions.

| Molecular formula: | C5H14N2 |

| Molecular weight: | 102.18 |

| CAS number: | 462-94-2 |

| ECS number: | 207-329-0 |

| Melting point: | 9.0℃ |

| Boiling point: | 178~180℃ |

| Application: | polyamide, pentamethylene diisocyanate(PDI), epoxy resin curing agent, organic synthesis intermediate, etc. |

| Item | Value |

| Appearance | colorless liquid, 25℃ |

| Content(%) | >99.5% |

| Water(mg/kg) | <5000 |

| Color | <8 |

Liquid status at room temperature. Can be transported directly in a drum or tank car.

-

Green and environmentally friendlyMade from bio-based and renewable resources, with a biological production process at room temperature and pressure, and friendly to the natural environment

Green and environmentally friendlyMade from bio-based and renewable resources, with a biological production process at room temperature and pressure, and friendly to the natural environment -

Low melting pointMelting point is 9 ℃. Liquid at normal temperatures, easier to operate and process

Low melting pointMelting point is 9 ℃. Liquid at normal temperatures, easier to operate and process -

Higher reactivityShorter carbon chain, lower molecular weight, higher reactivity and faster reaction speed

Higher reactivityShorter carbon chain, lower molecular weight, higher reactivity and faster reaction speed -

Higher strengthHigher density of functional groups due to its molecular structure, higher product strength

Higher strengthHigher density of functional groups due to its molecular structure, higher product strength -

New platform compoundNew platform compounds with huge scope for shaping more performance-advantaged, cost-effective polymers

New platform compoundNew platform compounds with huge scope for shaping more performance-advantaged, cost-effective polymers