ECOPENT® is a brand launched by Cathay Biotech for the engineering materials industry, to provide partially and entirely renewably sourced polyamide raw materials which are required for engineering plastics compounding. The renewable sources are plant raw materials. The bio-based content can be from 25% to 100%, which has been analytically verified by third-party authoritative laboratories performing ASTM 6866 methodology tests. ECOPENT® exhibits advantages regarding renewability, is recyclable, has a high performance and is cost-effective.

ECOPENT® products include general polyamides, high-temperature polyamides, long-chain polyamides, transparent polyamides etc. They exhibit excellent performance regarding flame resistance, impact resistance, anti-thermal aging, abrasion resistance, low warpage, high flowability and other properties.

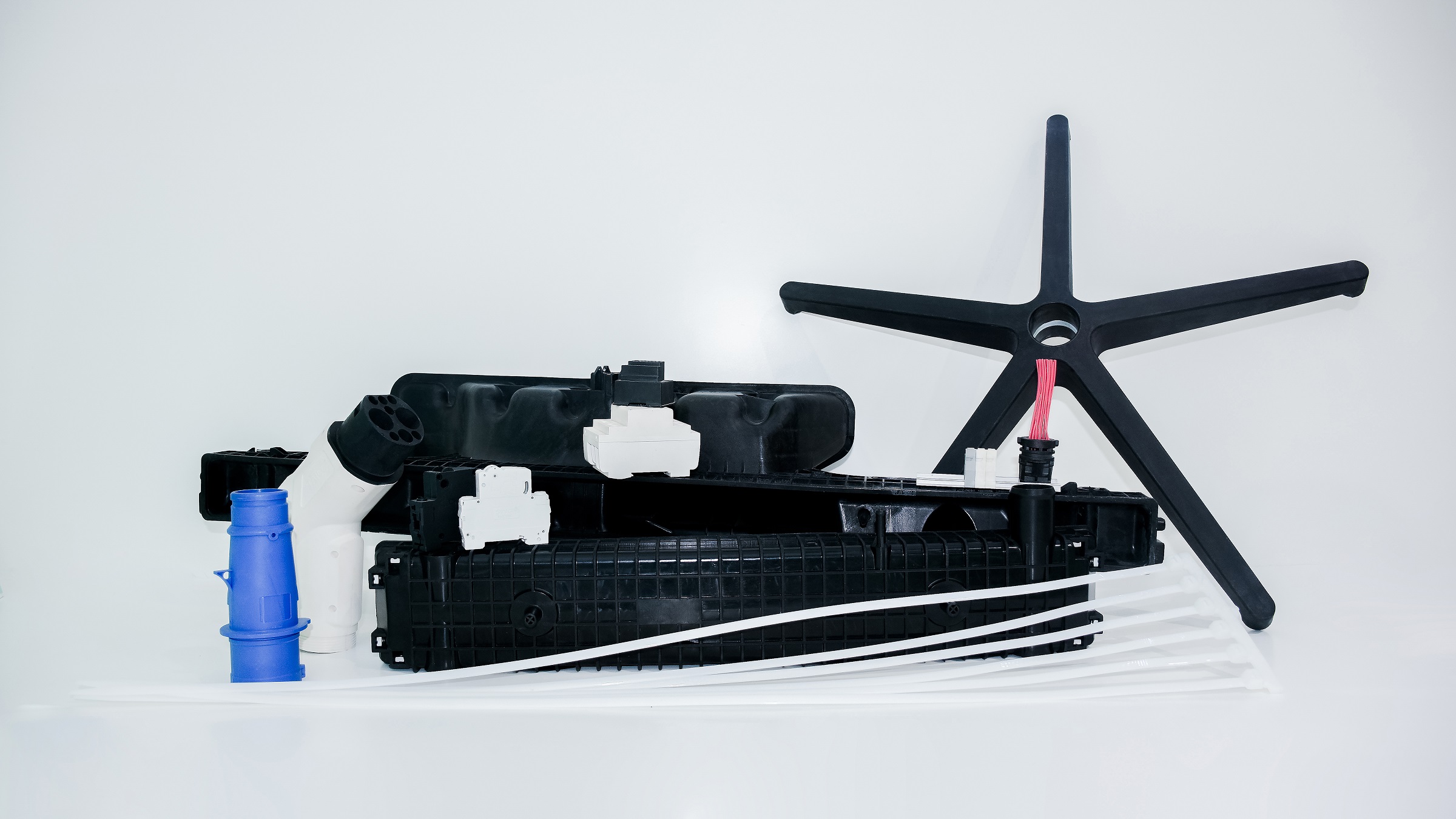

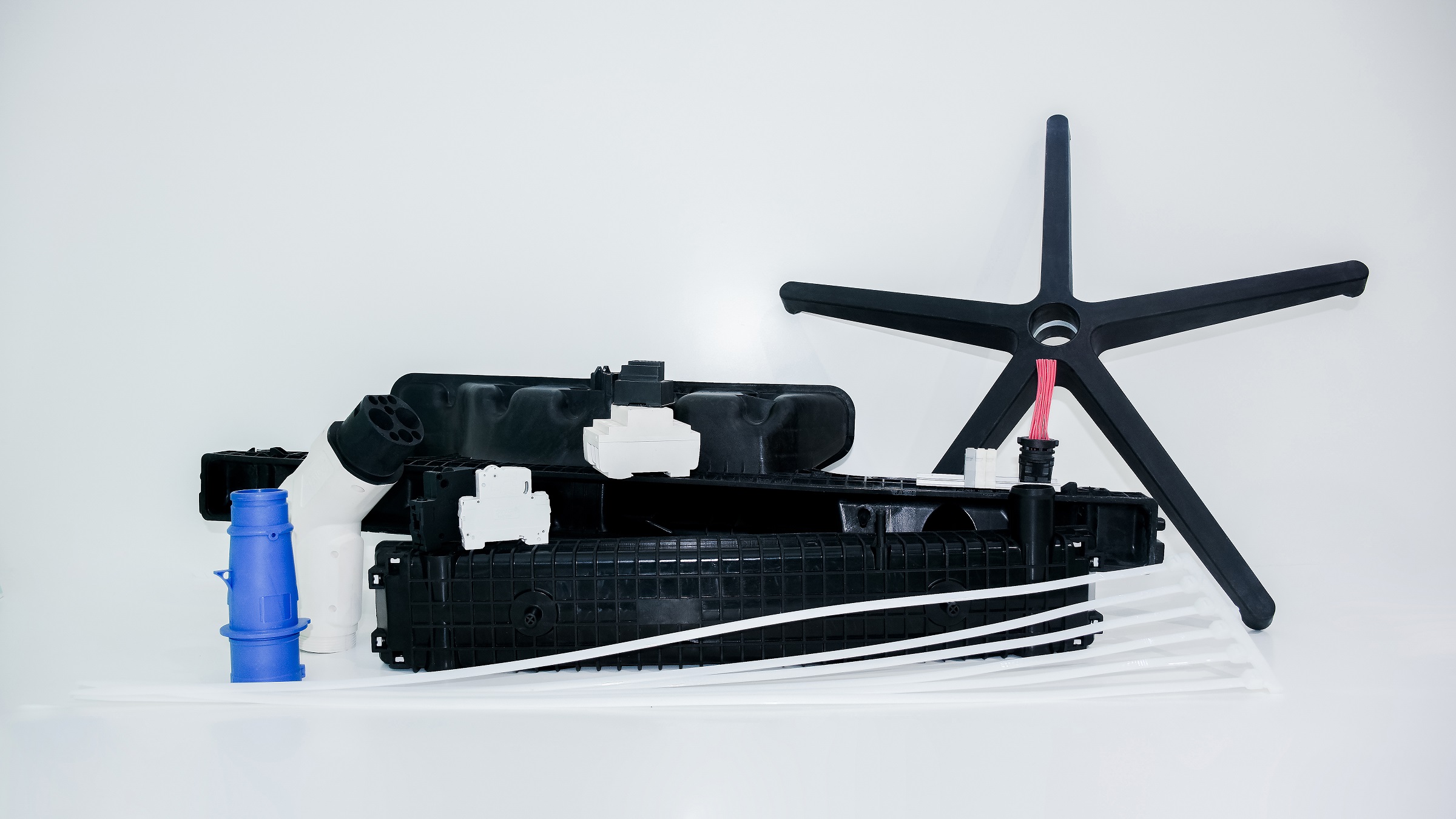

According to different product performance requirements of customers in the automotive and rail transit sectors, in electronics and electricals, in consumer and industrial goods, cable ties, film and other industries, Cathay can customize new, more technologically advanced, lower carbon and environmentally friendly bio-based material solutions.

| Performance Index | Test Method | Unit | E-1273 | E-2260 |

| IZOD notched impact | ISO 180 | KJ/m2 | 6.2 | 5.8 |

| Tensile strength | ISO 527 | MPa | 82.6 | 86.2 |

| Elongation at break | ISO 527 | % | 5.1 | 4.7 |

| Flexural modulus | ISO 178 | MPa | 2680 | 2720 |

| Flexural strength | ISO 178 | MPa | 118 | 130 |

| Heat deflection temp.(1.8MPa) | ISO 75 | ℃ | 74 | 76 |

| Vicat softening temp. | ISO 306 | ℃ | 219 | 229 |

| Melting point | ISO 11357 |

℃ |

<>254 | 269.4 |

| Rockwell hardness | ISO 2039-2 | - | 106L | 96.5L |

| Performance Index | Test Method | Unit | E-3100 | E-3300 |

| IZOD notched impact | ISO 180 | KJ/m2 | 6 | 5.79 |

| Tensile strength | ISO 527 |

MPa |

56.9 | 46.4 |

| Elongation at break | ISO 527 | % | >100 | - |

| Flexural modulus | ISO 178 | MPa | 1980 | 1597 |

| Flexural strength | ISO 178 |

MPa |

81.7 | 60.8 |

| Heat deflection temp.(1.8MPa) | ISO 75 |

℃ |

51 | 47 |

| Vicat softening temp. | ISO 306 |

℃ |

173 | 149 |

| Melting point | DSC | ℃ | 217 | 197.5 |

| Rockwell hardness | ISO 2039 | - | 95L | 58.2L |

| Performance Index | Test Method | Unit | E-5000 |

| Renewable carbon content | ASTM D6866 | KJ/m2 | 31 |

| Tg | ISO 11357 |

℃ |

150 |

| Heat deflectiong temp.(1.8MPa) | ISO 75 |

℃ |

115 |

| Transparency(560nm,2mm) | ASTM D1003 | % | 88.2 |

| Tensile strength | ISO 527 | MPa | 95 |

| Elongation at break | ISO 527 | % | >100 |

| Flexural strength | ISO 178-A | MPa | 117 |

| Flexural modulus | ISO 178-A | MPa | 2630 |

| IZOD notched impact(23℃) | ISO 180/IA | KJ/m2 | 12.7 |